Product Description

RoHS Compliant TI1 General Purpose Insulation PVC Compound 70 ℃ For USB Data Cable

Product Introduction:

PVC is one of the most widely used thermoplastic resins. It can be used to make products with high hardness and strength, such as pipes and fittings, profiled doors, windows and packaging sheets. It can also make soft products, such as films, sheets, electrical wires and cables, floorboards and synthetic leather, by addition of plasticizers.

1. Packing: 25Kg/bag internally film-coated polypropylene woven bags.

2. Storage : The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air.

3. Transportation : During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

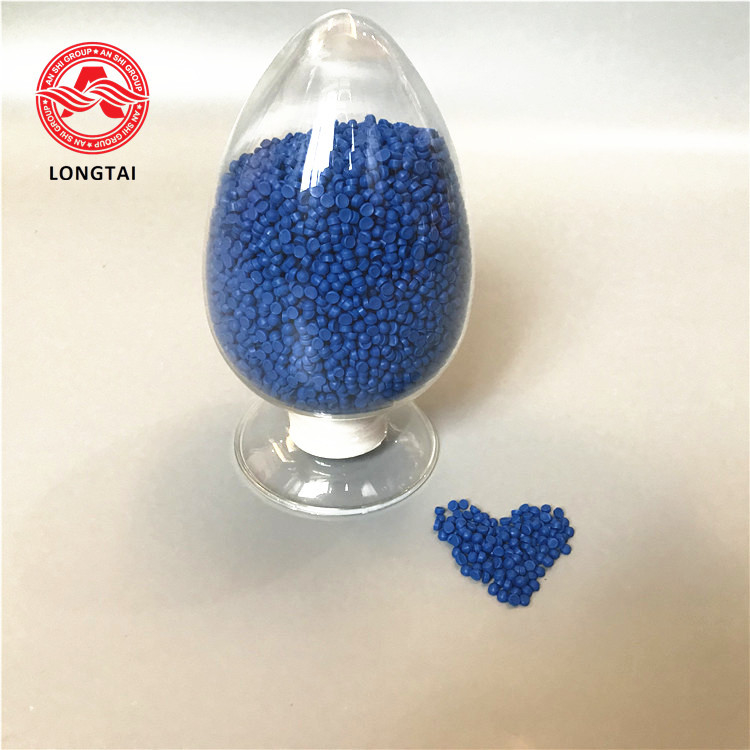

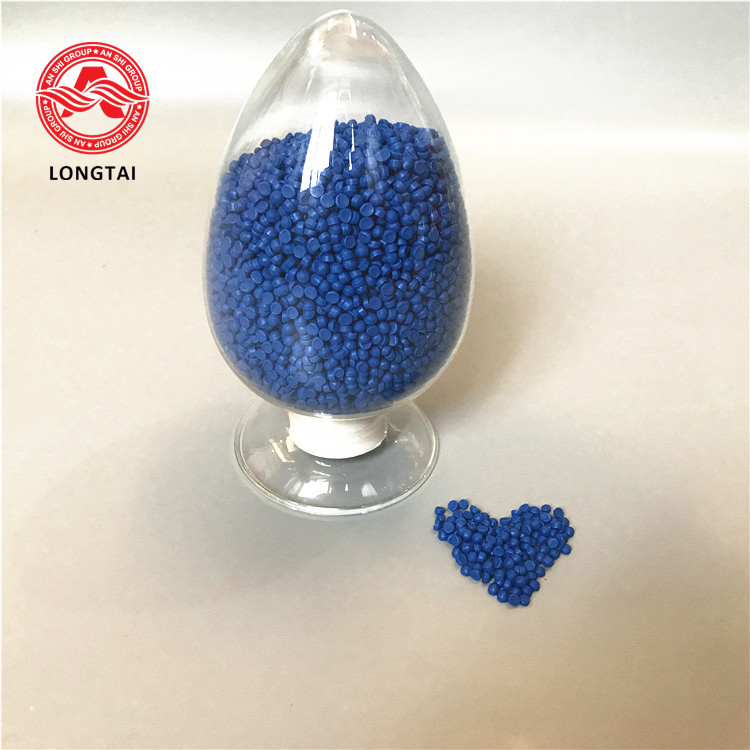

Pvc Granules For Electric Wire And Cable ,Insulation Jacket

Good processing technology, suitable to various cables.

Product Name:

- 70 ℃ PVC Cable Compound

- 90 ℃ PVC Cable Compound

- 105 ℃ PVC Cable Compound

- 105 ℃ Irradiated crosslinked FR PVC Compound

- 80 ℃ Irradiated crosslinked FR PVC Compound

- PVC Compound for Plug

Technical Data:

| Items |

Unit |

Typical Value |

Testing Method |

| 70 ℃ PVC Cable Compound |

105 ℃ PVC Cable Compound |

105 ℃ Irradiated crosslinked FR PVC Compound |

| Tensile Strength |

Mpa |

11 |

11 |

12 |

GB/T 1040.3-2006 |

| Elongation at Break |

% |

180 |

180 |

180 |

| Heat Aging |

|

|

|

|

|

| Testing Termperature |

℃ |

100 |

135 |

135 |

GB/T 8815-2008 |

| Testing Time |

h |

168 |

168 |

168 |

| Variation at tensile strength |

% |

20 |

20 |

20 |

| Variation at elongation |

% |

-15 |

-15 |

-15 |

| Low Temperature Brittleness |

℃ |

-20 |

-20 |

-20 |

GB/T 5470-2008 |

| Oxygen Index |

/ |

≥23 |

≥23 |

≥28 |

GB/T 2406.2-2008 |

| Density |

g/cm3 |

1.42 |

1.42 |

1.42 |

GB/T 1033.1-2008 |

| Hardness |

Shore A |

70-96 |

70-96 |

70-96 |

GB/T 2411-2008 |

Product Show:

How To order :

1. Let me know the models, specification, quantities, colors you want to order

2. We will email you the Proforma Invoice based on your order information

3. Kindly check the PI, everything is ok, we will start production as soon as receiving payment deposit or LC, then

deliver the goods on request, original documents will be send against full payment

FAQ:

Q: Do you provide samples? Is it free?

A: Free sample is accepted within 1kg if in stock but freight collected.

Q: What is your delivery time?

A: 3-7 days for sample order and 15-30 days after receiving deposit for bulk order.

Q: What’s the MOQ?

A: Most MOQ is 1000kg, parts of product is 100kg.

Q: What is your payment terms?

A: T/T, L/C, western Union are available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!