Product Description

UV And Weather Resistant Flame Retardant 88A 1.45g/CM3 PVC Compounds for Solar Cable

Company Profile.pdf

1.Technical Specifications

【1】Technical specifications of 70 ℃ pvc compound

| Tensile strength |

MPa |

20.5 |

| Fracture tensile strain |

% |

320 |

| Ageing temperature |

℃ |

100 |

| Ageing time |

h |

168 |

| Tensile strength after ageing |

MPa |

22.5 |

| Max change of tensile strength |

% |

+12 |

| After ageing fracture tensile strain |

% |

290 |

| Max change of fracture tensile strain |

% |

-10 |

| Thermal deformation |

% |

28 |

| Thermal ageing quality loss |

g/m2 |

19 |

| 200℃ thermal stability time |

min |

90 |

| 20℃ volume resistivity |

Ω.cm |

2.0*1011 |

【2】Technical specifications of 90 ℃ pvc compound

| Tensile strength |

MPa |

20 |

| Fracture tensile strain |

% |

330 |

| Ageing temperature |

℃ |

100 |

| Ageing time |

h |

240 |

| Tensile strength after ageing |

MPa |

21.5 |

| Max change of tensile strength |

% |

+8 |

| After ageing fracture tensile strain |

% |

310 |

| Max change of fracture tensile strain |

% |

-6 |

| Thermal deformation |

% |

28 |

| Thermal ageing quality loss |

g/m2 |

9 |

| 200℃ thermal stability time |

min |

120 |

| 20℃ volume resistivity |

Ω.cm |

2.0*1010 |

2.Use and standard: wire and cable

3.Process: extrusion

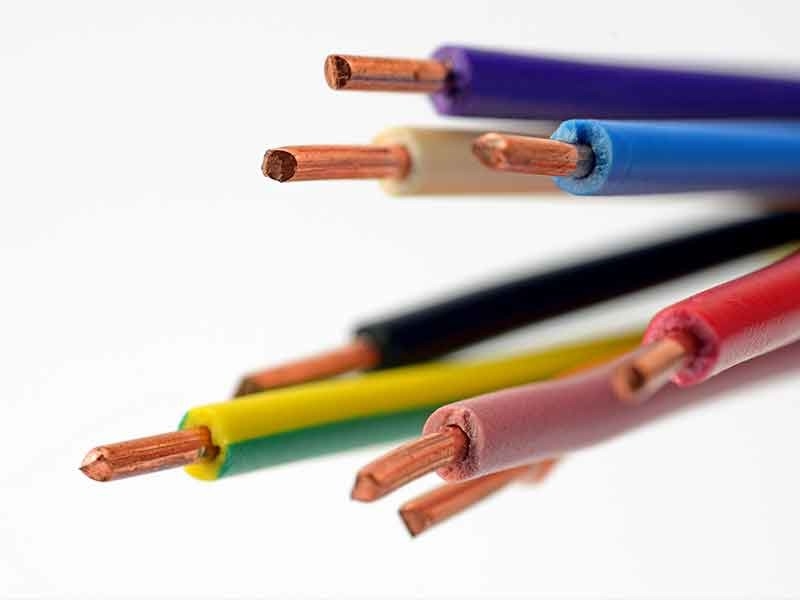

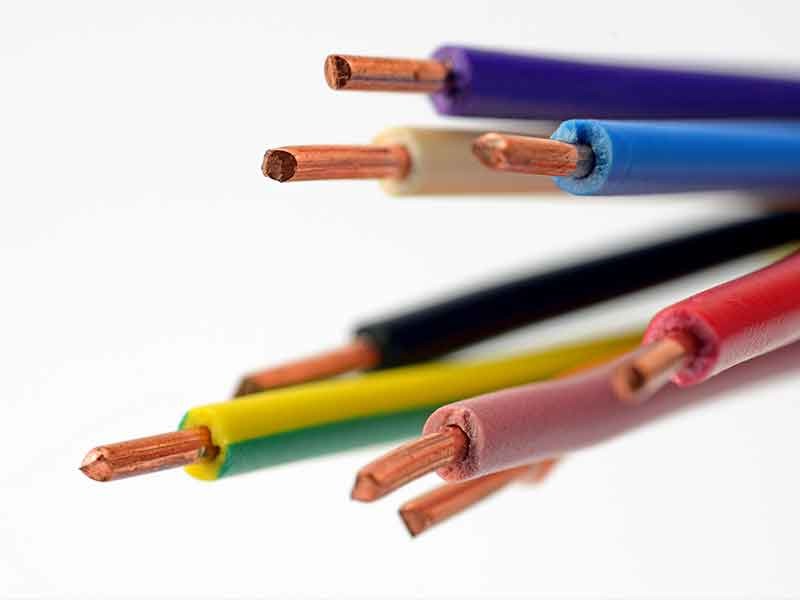

4.Appearance: cylindrical particles, plastication should be good, the color and luster is even, without obvious impurity.

5.color: Any colors, base on requirement.

6.Packing: 25kg net weight per in a kraft bag, 1000kgs/Jumbo bag ,We could support packaging agreed on by both manufacturer and client !

7. Transportation and storage:

This kind of product in the transportation should not be weathered, should be stored in a clean, cool, dry and ventilated warehouse , storage period is from the date for a year.

We will also produce the products according with customer's requirement, For example, Flame-resisting compounds, Low temperature resisting compounds, Heat-resistant compounds, and low smoke low halogen compounds, Transparent PVC compounds etc.

8.How To order :

1. Let me know the models, specification, quantities, colors you want to order

2. We will email you the Proforma Invoice based on your order information

3. Kindly check the PI, everything is ok, we will start production as soon as receiving payment deposit or LC, then

deliver the goods on request, original documents will be sent against full payment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!