Product Description

PVC Compounds for extrusion of wires & cables with Low Smoke and Gas evolution properties

About PVC Compounds:

Cable PVC compounds are thermoplastic materials derived from processing polyvinylchloride compositions, produced as granules. Various properties are imparted to compounds depending on applications and item operation conditions. This is achieved by using plasticizers, stabilizers and modifiers in various combinations in compositions.

PVC based plasticizers have considerable mechanical strength and water resistance, high thermal resistance to low temperatures, good insulation properties, insoluble in gasoline and kerosene, abrasion, acid and alkali resistant. PVC based compounds are readily welded and glued.

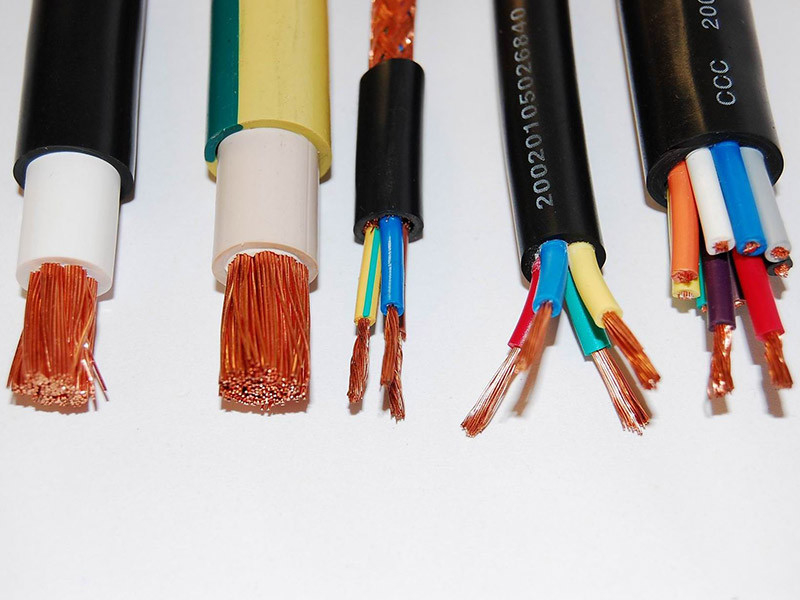

Cable PVC compounds are use in the cable and conductor industry for manufacture of insulation and protective wire and cable sheaths. The main final consumers of the PVC based cable and conductor products are energy and construction industries.

1. Use and standard: wire and cable

2. Process: extrusion

3. Appearance: cylindrical particles, plastication should be good, the color and luster is even, without obvious impurity.

4. Color: Any colors, base on requirement.

5. Packing: net weight 25kg or 650~850kg per bag.

|

|

|

|

|

Common Insulation

Component Wire Material

|

Passed UL test, Cold-form test -20 ℃,

Heat resistance

grade: 60℃ 75℃ 90℃ 105℃,

Combustion test: VW-1 FT2, Environment friendly.

|

Suites for various indoor insulation

component wire material.

|

|

Cold – Resistant Insulation

Component Wire Material

|

Passed UL test, Cold-form test -40 ℃, Heat resistance grade:

60℃ 75℃ 90℃ 105℃,

Combustion test: VW-1 FT2, Environment friendly.

|

Suits for outdoor -40℃ cold – resistant insulation component

wire material

|

Flexible or plasticizer PVC has been used to produce cable and wire insulation and sheathing for more than 50 years. The performance specification for PVC formulations employed for wire and cable coating or jacketing depends upon the nature of the wire and cable and the use to which it is to be put. Typically, wire and cables in automobiles are required to withstand temperatures as high as 150°C due to the heat generated by the passage of electricity through the cable and as low as -40°C to ensure the insulation is preserved if the automobile is subject to extreme weather conditions. Low temperature performance is also required for cables such as outdoor extension cables that are used in cold climates.

Here are two examples:

Softener formulation adjustment can raise the continuous operating temperature limit to 105°C.

Aluminium trihydroxide (ATH) additive can systematically reduce flammability and smoke formation. Regulatory authorities such as the VDE, EN or UL issue standardized property profiles for insulation and coating compounds.

Cable PVC Compounds Types:

- 70 ℃ PVC Cable Compound

- 90 ℃ PVC Cable Compound

- 105 ℃ PVC Cable Compound

- 105 ℃ Irradiated crosslinked FR PVC Compound

- 80 ℃ Irradiated crosslinked FR PVC Compound

- PVC Compound for Plug

Technical Data:

| Items |

Unit |

Typical Value |

Testing Method |

| 70 ℃ PVC Cable Compound |

105 ℃ PVC Cable Compound |

105 ℃ Irradiated crosslinked FR PVC Compound |

| Tensile Strength |

Mpa |

11 |

11 |

12 |

GB/T 1040.3-2006 |

| Elongation at Break |

% |

180 |

180 |

180 |

| Heat Aging |

|

|

|

|

|

| Testing Termperature |

℃ |

100 |

135 |

135 |

GB/T 8815-2008 |

| Testing Time |

h |

168 |

168 |

168 |

| Variation at tensile strength |

% |

20 |

20 |

20 |

| Variation at elongation |

% |

-15 |

-15 |

-15 |

| Low Temperature Brittleness |

℃ |

-20 |

-20 |

-20 |

GB/T 5470-2008 |

| Oxygen Index |

/ |

≥23 |

≥23 |

≥28 |

GB/T 2406.2-2008 |

| Density |

g/cm3 |

1.42 |

1.42 |

1.42 |

GB/T 1033.1-2008 |

| Hardness |

Shore A |

70-96 |

70-96 |

70-96 |

GB/T 2411-2008 |

About us:

Jiangxi Longtai New Material Co., Ltd, founded in 2002, was successfully listed the New OTC Market in 2016, stock code: 836898. Longtai is specialized in the development and sales of all kinds of new materials, wire&cable materials and ariculture products. It has passed ISO9001:2008. All product meet RoHS and REACH by SGS. More than 30% of products are exported to Europe, America, Janpan, Southeast Asia and Africa, and so on.

Main Products:

1. fibrillatedPP twine,PP rope,PP split film rope,PP packing rope,baler twine,banana rope,all kinds of agricultural rope,garden rope.

2.PP cable filler yarn,optical cable filler yarn,flame retardant filler yarn,Halogen FR PP filler,cable material.

3.Sewing thread,polyester thread,nylon thread,polyester twine.

4.Cotton yarn,cotton twine,and recycled cotton yarn.

5.Aramid yarn,polyester yarn,nylon yarn and other special fiber.

6.Cotton paper,AL-PET tape,glass fiber and other filling and shielding materials.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!