Product Description

Good Quality Low Smoke Halogan Free Special FR PVC Compound Sheathing 90℃ UV Resistance

Cable Grade PVC compound professional manufacturer. Specialized in the development and sales of all kinds of cable filling Materials,Wire & Cable wrapping film and PVC compound.our company is National High-tech Enterprises verified a number of patents and Applicability of Patents.We're professional manufacture for supplying Power Cable PVC Compounds,Electric Power Cable & Power Cable PVC Compounds,UL Compounds,Automotive Wire & Cable Compounds,Elastomeric Compounds,The Special PVC Compounds,TPE Compounds,Ceranic Flame Retardant & Refractory Compounds.

We will also produce the products according with customer's requirement, For example, Flame-resisting compounds, Low temperature resisting compounds, Heat-resistant compounds, and low smoke low halogen compounds, Transparent PVC compounds etc.

1.Technical Specifications

| Test No: SY18170328A |

Test Date:Mar28.2017-Apr.06.2017 |

| Sample Name: J1772 |

MFG Date: Mar 23,2017 |

| Test Reference: UL62&UL2556 |

Insulation P/N: Black Jacket |

| Item |

Requirement |

Test Results |

Remark |

| Jacket |

Size of Insulator |

mm² |

13.86 |

T:2.31mm W: 6.0mm |

| Before Ageing |

Elongation at Break |

> 200% |

410 405 410 |

Velocity of the tester 500±25mm/mikn |

| Pull Force |

KGF |

12.38 12.49 13.53 |

| Tensile Strength |

>085KGF/mm² |

0.89 0.90 0.98 |

| After Ageing (105 ℃) |

Elongation at Break |

> % |

425 435 435 |

Test Period: 16:00 Mar.29- 16:00 Apr 05 |

| Pull Force |

KGF |

14.02 12.63 12.73 |

| Tensile Strength |

>KGF/mm² |

1.01 0.91 0.92 |

|

| The Remain Elongtaion Rate |

> 75% |

104 107 107 |

Temperature:136 ℃ Duration:168h |

| The Remain Tensile Strength Rate |

> 75% |

110 99 100 |

| Jacket Oil Aging Test |

Elongation at Break |

> % |

310 320 320 |

Test Period: 16:00 Mar.29- 16:00 Apr 05 |

| Pull Force |

KGF |

10.34 10.57 10.77 |

| Tensile Strength |

>KGF/mm² |

0.75 0.76 0.78 |

|

| The Remain Elongtaion Rate |

> 75% |

76 78 78 |

Temperature:136 ℃ Duration:168h |

| The Remain Tensile Strength Rate |

> 75% |

82 83 85 |

| Electrical Performance |

Jacket Resistance Test |

> 100MΩ |

246.3 GΩ |

DC: 500V/1min |

| Physical Performance |

Heat Deformation Test |

< 50% |

47.6 45.8 46.7 |

150℃ X 1h X 2000g |

| Heat Shock Test |

without cracking |

without cracking |

150℃ X 1hX Ø34.9mm |

| Cold Impact Test |

|

Cable Without Cracking |

|

| Cold Bend Test |

without cracking |

without cracking |

‘- 40℃X 4h X Ø31.8mm |

| Flammability Test (FT-1) |

a. The delay time at every time is not more than 60s after remove flame; b. The bumed area of indication flag on the testing sample is not more than 25% |

ok |

|

| Flammability Test (FT-2) |

1.The length of the charred portion of the specimen of cord shall not exceed 100mm not shall flaming particles ignitecotton. 2. Flameless charring of the cotton shall be ignored |

< 100mm |

|

| Cable Flexibility Test |

Coil 10ft of cable into a cyliner with an inner diameter that is between 260 and 275 mm in diameter (a typical US 5 gal bucket has this diameter) in a single layer with no gaps between the coils. The end of the cable on the top winding is secured to the 2nd turn of the coil. Place the cable and cylinder sample inside a chamber that has been preconditioned to minus -30 ℃ with uncontrolled humidity and leave it for a minimun of 2 hours, Remove the sample from th cylinder and support the top turn of cable at the top of the coil 4 feet above the floor or supporting surface, then allow the other end of the cable to descend under its own weight. Measure the time that it takes for the cable to first touch the floor or supporting surface. Pass/ Fail: if the end of the cable reaches the supporting surface within 2 minutes for the 32 A cable, the criteria is met, 16A cable TBD |

Time is 97 seconds cable reaches the supporting surface |

2.Use and standard: normally for cable and wire

3.Process: extrusion

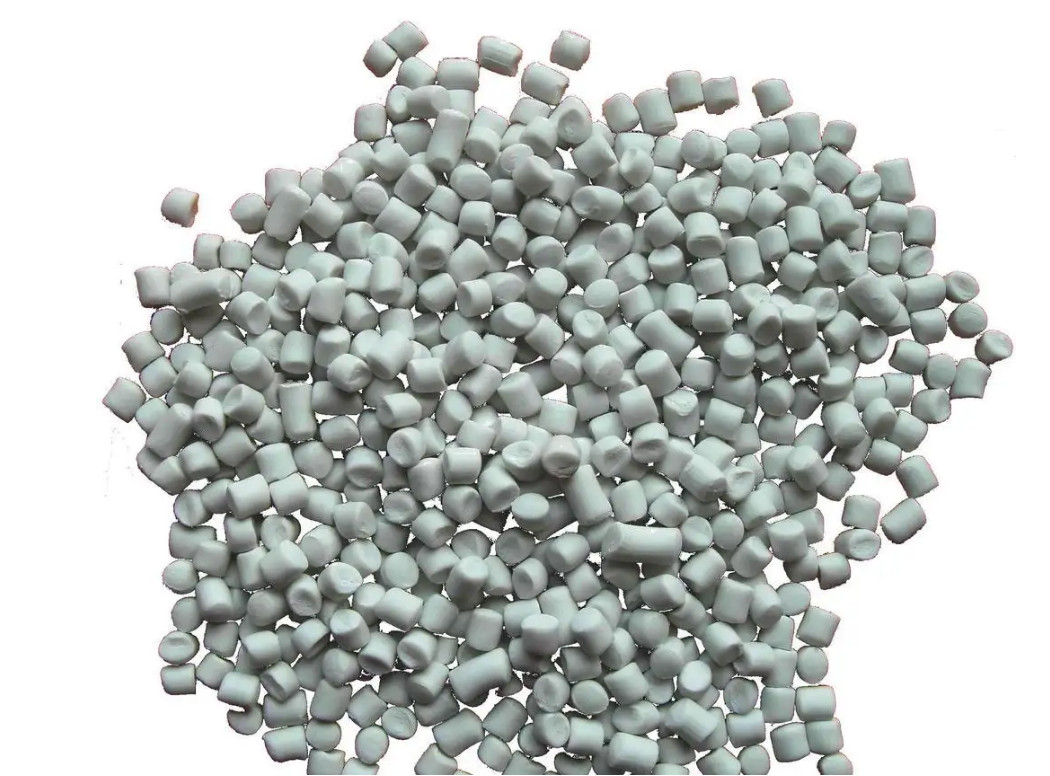

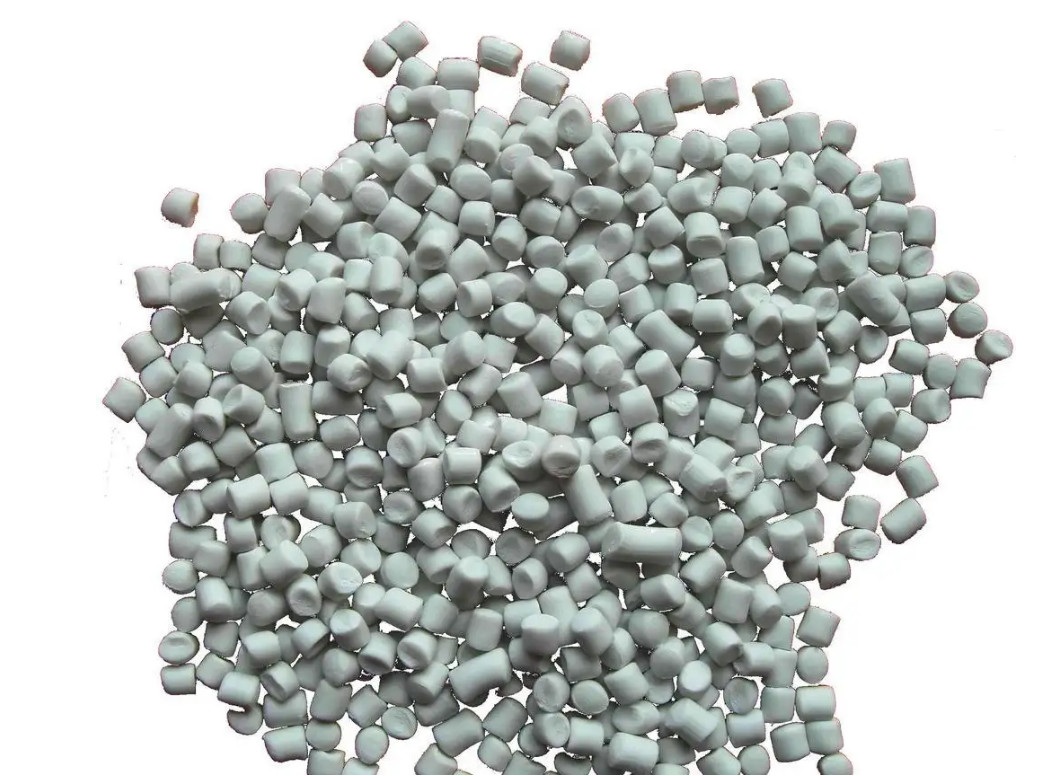

4.Appearance: cylindrical particles, plastication should be good, the color and luster is even, without obvious impurity.

5.color: Any colors, base on requirement.

Black and white, gre for Shealthing PVC compound

Red, Yellow, Blue, White and black for Insulation PVC compound

6.Packing: 25kg net weight per in a kraft bag,We could support packaging agreed on by both manufacturer and client !

20 Tons per 20GP, 26Tons per 40GP

7. Transportation and Storage:

This kind of product in the transportation should not be weathered, should be stored in a clean, cool, dry and ventilated warehouse , storage period is from the date for a year.

8.Factory Introduction:

Our factory is located in Shangyou industrial zone, Shangyou country,Ganzhou city,Jiangxi province, and setting up sales office and warehouse in Dongguan city. The new and standard factory is built on 40,000 sq. mtr with a total annual capacity of approximately 10,000 tons of various products,covers 2 flame retardant production-line, 7 cable filler yarn production-line,32 twisted machine, with full modernization of testing equipment. All of the products can be exported freely.

The company has passed the ISO 9001:2008 quality system certification. Each of these products can reach to environmental requirement by SGS company: such as ROHS, REACH-SVHC, Halogen Free. More than 30% of products are exported to Europe, America, Japan, Southeast Asia and Africa, having cooperation with many well-known listed companies at home and abroad.

We always sincerely welcome any domestic and overseas customers with great enthusiasm.

9.How To order :

1. Let me know the models, specification, quantities, colors you want to order

2. We will email you the Proforma Invoice based on your order information

3. Kindly check the PI, everything is ok, we will start production as soon as receiving payment deposit or LC, then

deliver the goods on request, original documents will be send against full payment

10,Product show:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!