Product Description

Low Smoke Halogen Free Flame Retardant Tape

Product Description

Low smoke halogen free flame retardant tape is a flame retardant tape material made of glass fiber cloth as the base material, dip-coated with configured metal hydrate and halogen-free flame retardant glue solutions in a certain proportion on its upper and lower surfaces, baked, cured and slit.

The low smoke halogen free flame retardant tape is suitable for use as wrapping tape and oxygen-insulation flame-retardant layer in all kinds of flame-retardant cable and fire-resistant cable. When the cable is burning, the low smoke halogen-free flame retardant tape can absorb a lot of heat, forming a heat insulation and oxygen resistance carbonized layer, isolating oxygen, protecting the cable insulation layer from burning, preventing the flame from spreading over the cable, and ensuring the normal operation of the cable within a certain period of time.

Low smoke and halogen-free flame retardant tape produces very little smoke when burning, and no toxic gas is produced, which will not cause ‘secondary disaster’ during fire. Combined with the low smoke and halogen-free flame retardant outer sheath layer, the cable can meet the requirements of different flame retardant grades.

Low smoke halogen-free flame retardant tape not only has high flame retardancy, but also has good mechanical properties and soft texture, which makes the cable core bind more firmly and maintains the stability of the cable core structure. It is non-toxic, odorless, non-polluting when used, does not affect the current carrying capacity of the cable during the operation, has good long-term stability.

Application

Mainly used as core bundling and oxygen-insulation flame-retardant layer of all kinds of flame-retardant cable, fire-resistant cable.

Technical Parameters

| Item |

Technical Parameters |

| Nominal Thickness (mm) |

0.15 |

0.17 |

0.18 |

0.2 |

| Unit weight in grams (g/m2) |

180±20 |

200±20 |

215±20 |

220±20 |

| Tensile strength (longitudinal) (N/25mm) |

≥300 |

| Oxygen Index (%) |

≥55 |

| Smoke Density (Dm) |

≤100 |

Corrosive gases released by combustion

pH of aqueous solution

Conductivity of aqueous solution (μS/mm) |

≥4.3

≤4.0 |

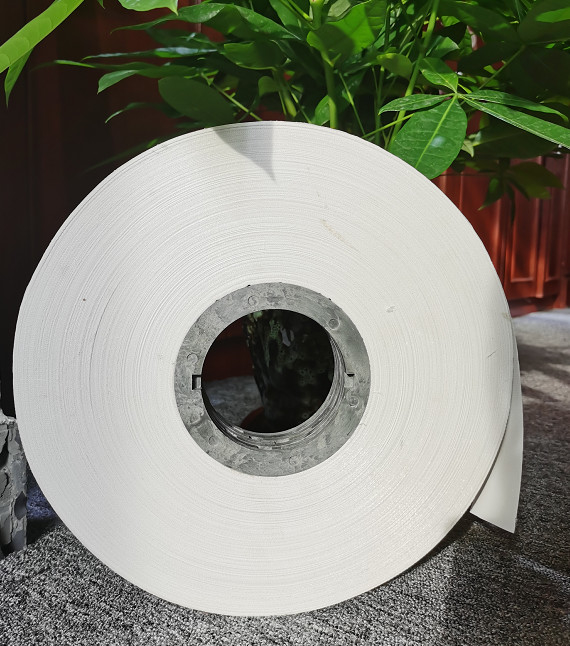

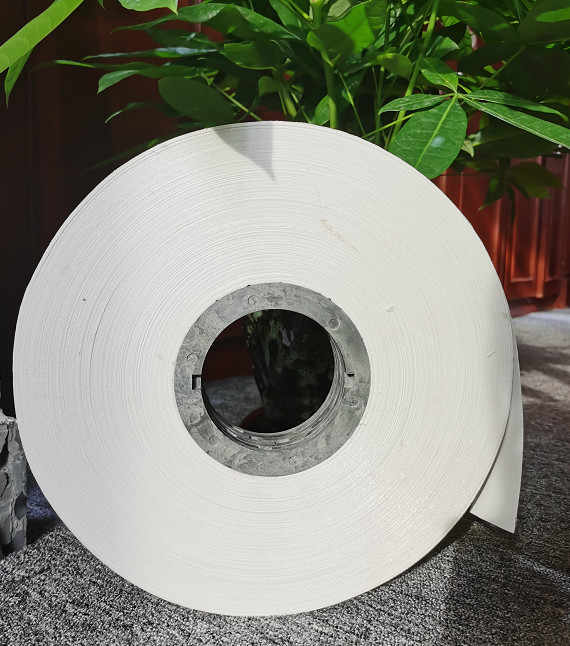

Product Show

Packaging

The product will be packed in paper carton with PE film bag and bubble paper inside. It is then sealed and inserted in a wooden case or packed on a wooden pallet. After it is fixed, an external plastic coversheet is wrapped around it to avoid water penetration.

Storage Information

The product has a shelf life of 12 months from production date if stored in unopened original packages, under dry and clean conditions at temperatures between 10-30°C. The product will be damaged if it is stored in a moist area or if it gets in contact with water.

1) The product shall be kept in a clean, dry and ventilated warehouse.

2) The product should not be stacked together with flammable products and should not be close to fire sources.

3) The product should avoid direct sunlight and rain.

4) The product should be packed completely to avoid moisture and pollution.

5) The product shall be protected from heavy pressure and other mechanical damage during storage.

6) The storage period of the product at ordinary temperature is 6 months from the date of production. More than 6 months storage period, the product should be re-examined and only used after passing the inspection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!